Bacterial filtering plant – step 1

I work at Old Mutual at Mutualpark in Cape Town. It is a massive campus of several buildings serving about 10 000 people. To provide water for that many people requires about 450 000l water per day; that amounts to about 45l per person total (this is total consumption including the restaurants, kitchens, aircon units etc). So I think it’s a remarkable achievement that they managed to get the entire campus off the water grid by building an onsite world-class water recycling plant.

Storage tanks

The main source of recycling water is waste water from the campus – yes every time you flush or wash your hands the output is recycled into drinking water, and its supplemented with grey water from the city (which then also goes through the filtration system). No city drinking water is needed.

Sand filtering – step 2

I was very lucky to go on a tour of the plant, and its impressive. It is capable of generating up to 800 000l water per day; that is almost double what is required on the campus. The water is super-clean, is tested everyday, and is compliant will the regular legal requirements (SANS 241 to be specific). It is the first privately developed waste water filtration plant in South Africa and can supply water to the campus without any clean municipal water required. None at all!

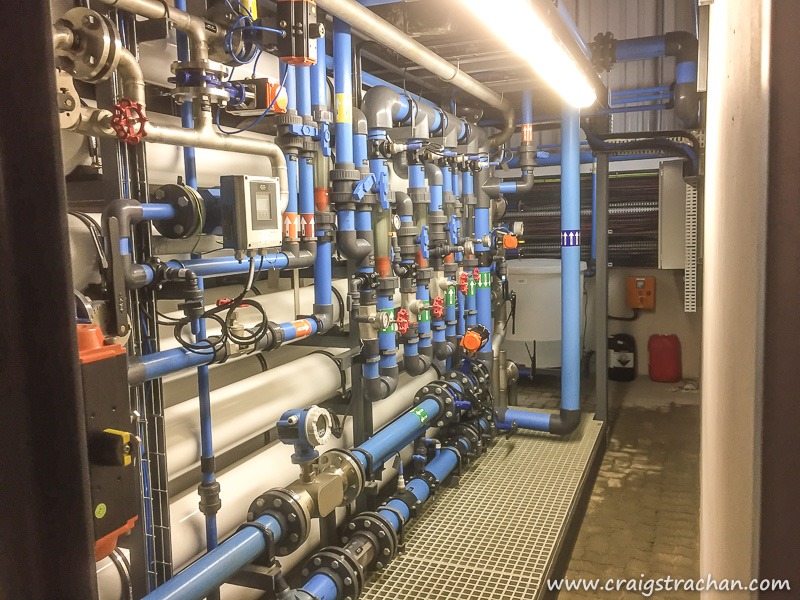

Reverse osmosis – step 3

Note: I mentioned 3 steps but that is massively simplified; it is a complex multi-step filtration system they use.

So between the solar panels, waste recycling and now water recycling I think they are doing a good job with the environment. And it makes business sense. The water plant will only need a few years to pay for itself. This is what large companies should be doing.

Leave a Comment